Aluminum Industry

Designed To Reduce Your Costs

Our Latest Aluminium Technologies

Light and Flexible

We offer a lighter version of its trusted KWD mesh belt shot blast machine range. The mesh belt concept allows the efficient blasting of parts from all sides within a relatively compact space and without tumbling.

Delivery:

6weeks+

Technology:

Blast wheelST SmartLine Overhead Rail Machine

Assemble, connect and blast. Immediately ready for use and complete with two blast wheels, you can be in production from day one.

Delivery:

9weeks+

Technology:

Blast wheel

HT Pass-through Monorail machine

HT pass through moorail blast machine will serve many applications.

Delivery:

9weeks+

Technology:

Blast wheel

HG C Pass-through shot blasting

Achieve shot blasting times due to a combination of the latest transport technology and highly efficient blast wheels.

Delivery:

9weeks+

Technology:

Blast wheel

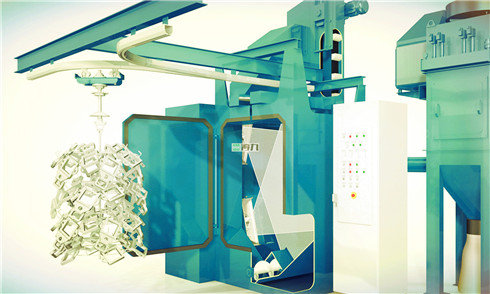

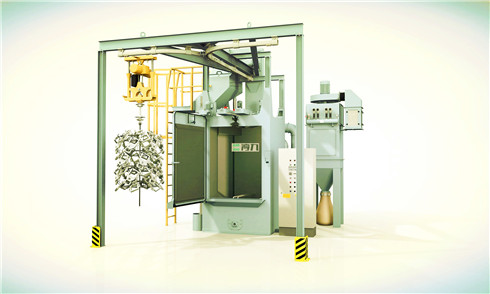

KZP Spinner Hanger machine

KZPSpinner hanger machine applied for surface treatment and deburring of aluminum parts,descaling of forgins,and sand removal from castings,especially for those workpiece which are not suitable for tumbling because of their shape or size.

Delivery:

12-19weeks

Technology:

Blast wheel

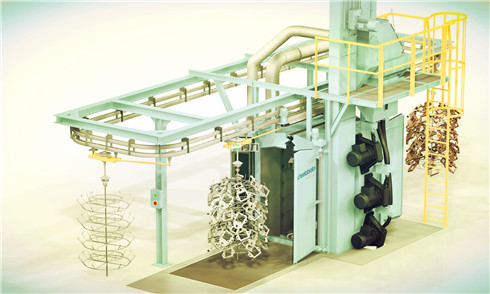

HSKHnager type machine

KNNJOO hanger type shot blasting machine offers total flexibility for your surface preparation requirements.

Read More

Delivery:

12weeks+

Technology:

Blast wheel

CND Batch type tumblast machine

Compact batch machine design with a simple operating principle to deliver forced but gentle turning.

Delivery:

12-9weeks

Technology:

Blast wheel

KWDWire Mesh Belt Machine

KNNJOO mesh belt shot blasting machine efficiently blast both flat or very complex parts in a pass-through process.

Delivery:

9weeks+

Technology:

Blast wheel

Robot Gripper

Robot gripper machines are ideal for the removal of the fire cracks,for shot peening and the blasting of the filigree parts.

Delivery:

9 weeks+

Technology:

Blast wheel

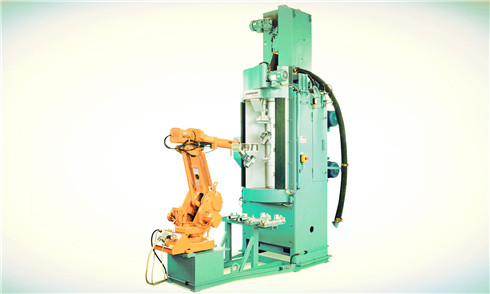

KM Robot Manipukator

KMSystem is designed to accommodate specific requirements for shot blasting workpieces of light metal or magnesium alloys.

Delivery:

9weeks+

Technology:

Blast wheel

Wire coiled shot blasting machine

his machine is the best special equipment to clean the disc round wire , the use of the surface layer of scale blasting process clear and steel wire surface oxide formed by rolling.

Delivery:

9weeks+

Technology:

Blast wheel

Chain anchor shot blasting machine

Chain anchor shot blasting machine system, single cleaning, extremely fast.

Delivery:

6weeks+

Technology:

Blast wheel

Compsct Machine

Asuper-compact blast machine for aluminum cast parts

Aluminium Smelters

Aluminum Smelters worldwide use carbon blocks as "sacrificial" anodes to produce primary aluminium. But anode assemblies are valuable production tools and investment assets which can be re-used after careful and effective treatment of their main components, under specific technological conditions. The wheel blast process, as applied by KNNJOO, can achieve this treatment efficiently, and the KNNJOO range of products includes proven machinery systems for all needs.

Typical applications include the cleaning of carbon butts with removal of all residuals, as well as the cleaning stub rods, thimbles, cathode bars and baked anodes.