Forgings and Casting Applications

Foundry Castings

Forged Parts

Blast cleaning is employed to remove scale from forged parts. KNNJOO has vast experience in such applications and can supply a number of well proven shot blast machines which are designed to help you to lower your cost per part produced whilst delivering productivity and quality gains.

Machine Selection

Tumbleproof Workpieces

- Tumblastand drum type blast machines are available in a multitude of sizes, and with variable loading and unloading principles.

-

Continuous tumblast(CT and DT machines) achieve a more cost-effective and efficient process when large numbers of parts need to be blasted throughout the shift. Production processes become more automated and less space is used.

Delivery:

12-18weeks

Technology:

Blast wheelGN Batch type tumblast machine

GN Tumblast design with a simple operating principle to deliver forced but gentle turning and tumbling parts.

Delivery:

18weeks+

Technology:

Blast wheel

CNDBatch type blast cleaning machine

KNNJOO CND machines are proven in the thousands of applications and constiture reliable process technology.

Delivery:

18weeks+

Technology:

Blast wheel

CT Through-feed blast cleaning machine

This machine are situated within either an automated process or a continuous production line.

Delivery:

18weeks+

Technology:

Blast wheel

DT Through-feed Rocker Barrel Machine

The polygon shaped trough rocks back and forth to gently tumble the workpieces.

Thin-Walled And/Or Delicate Workpieces

- Turntbable machine are ideal for small to medium sized loads.

- Wire Mesh belt machines

- Robot gripper machines

Delivery:

7weeks+

Technlogy:

Blast wheelRotary Table machine

Knnjoo table blast machines, the industry standard - from the most simple applications to batches of up to 120 tons. Talk to Wheelabrator.

Delivery:

9weeks+

Technlogy:

Blast wheel

Wire Mesh belt machine

Designed for cleaning a variety of parts that range from die-cast transmission housing with hard to reach areas to simple workpieces and components.

Delivery:

15weeks+

Technlogy:

Blast wheel

Robot Gripper

Robot gripper machines are ideal for the removal of fire cracks,fo shot peening and the blasting of filigree parts.

High Performance Processing of Complex Parts

e.g. crankcases, cylinder heads, gear housings

-

Robot gripper blast machines can clean interior areas without accumulation of abrasive. Single or pairs of components can be desanded, decored and/or peened.

Delivery:

18weeks+

Technology:

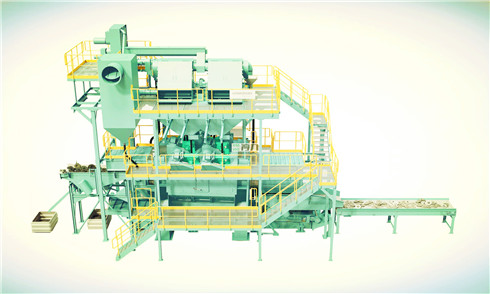

Blast wheelMAC Robot Manipulator system

MAC system is designed to accommodate specific requirements for shot blasting workpieces of light metal or magnesium alloys and has an internal manipulator to remove the workpiece in blast stream.

Delivery:

18weeks+

Technology:

Blast wheel

Manipulator Systems

These systems meet the highest production demands and are renowned for their excellent blast cleaning performance for components of different shapes and sizes.

For Parts Susceptible To Impact Damage

- Hanger-type machine are ideal for parts that can not be tumbled, and offer the added advantage that batches can be prepared or unloaded whilst one batch is being processed.

-

Continuous conveyor machined、Wire Mesh Blast and inclined belt machines allow smooth and shockless continuous blast cleaning for shock and vibration sensitive parts

e.g. brake drums, brake disks, wheel rims, etc.

Delivery:

18weeks+

Technology:

Blast wheel

HPS Hanger Type Machine

Standard solution ideal for foundry and forge applications,including cast,forge or hardened parts.

Delivery:

18weeks+

Technology:

Blast wheel

PL Overhead Monorail machine

KNNJOO machine include a number of heavy dust variations for different production areas,e.g. foundries and forges.

Delivery:

18weeks+

Technology:

Blast wheel

KZP Spinner-hanger machine

he machines with two or three chambers are applied for surface treatment and deburring of aluminum parts, descaling of forgings, and sand removal from castings.

Delivery::

18weeks+

Technology:

Blast wheel

CNDTilting drum machine

Safe shot blasting of rotationally symmetric workpieces

Delivery::

12-18week

Technology:

Blast wheel

KWD Mesh belt machine

KNNJOO Mesh belt shot blasting machines efficiently blast both flat or very complex parts in a pass-through procecss.

Delivery::

18weeks+

Technology:

Blast wheel

ZT Double rotary machine

Double rotary shot blasting machines are used for process-safe desanding of cast parts or for descaling forged rotating parts.

For thecomplete foundry solutionncluding moulding machinery, please consult theHome of the site.