How to select suitable cleaning equipment for castings

To select suitable cleaning equipment for castings, here are some guidelines:

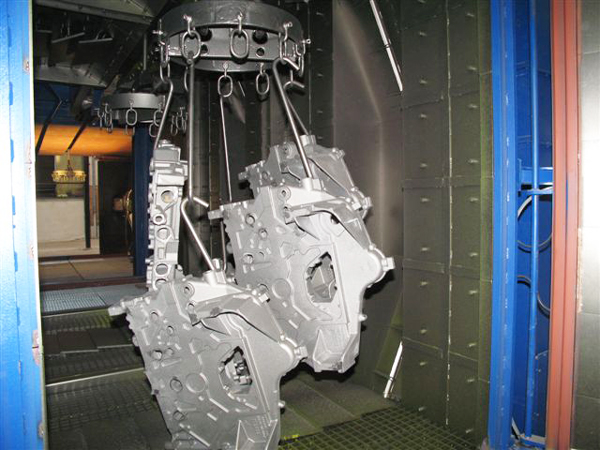

Cleaning Method: Determine the appropriate cleaning method based on the type and size of the castings, as well as the level of cleanliness required. Common cleaning methods include shot blasting, sandblasting, ultrasonic cleaning, and chemical cleaning. Each method has its advantages and is suitable for different types of castings.

Cleaning Efficiency: Consider the cleaning efficiency of the equipment. It should be capable of effectively removing contaminants such as sand, scale, and residual molding materials from the castings. Evaluate the equipment's cleaning performance and ensure it meets the desired cleanliness standards.

Equipment Capacity: Choose cleaning equipment that matches the production capacity and workload of your casting operations. The equipment should be able to handle the size, weight, and quantity of castings efficiently. Consider factors such as cycle time, loading capacity, and production output to ensure smooth operations.

Automation and Integration: Depending on your production requirements, consider whether you need automated cleaning equipment or integration with other processes. Automation can improve efficiency and reduce labor costs, especially for high-volume production. Integration with other processes, such as robotic handling or conveyor systems, can streamline the overall casting cleaning process.

Maintenance and Durability: Assess the maintenance requirements and durability of the equipment. Look for equipment that is easy to maintain, with readily available spare parts and a reliable service network. Robust construction and quality components ensure the equipment's longevity, minimizing downtime and repair costs.

Environmental Considerations: Take into account environmental factors such as dust emissions, wastewater treatment, and noise levels. Choose equipment that complies with environmental regulations and incorporates features for dust collection, water recycling, and noise reduction.

Cost Considerations: Evaluate the overall cost of the equipment, including the initial investment, operating costs, and maintenance expenses. Consider the long-term return on investment and compare different equipment options to make an informed decision.

Expert Consultation: Consult with experienced engineers or suppliers specializing in casting cleaning equipment. They can provide valuable insights and recommend suitable equipment based on your specific requirements.